Micrometer Screw gauge: Definition, least count & Applications

Micrometer screw gauge is an instrument used to measure the diameter of thin wires, the thickness of small sheets of glass, plastic, etc. It can measure up-to 1/10 of mm (or 0.01 mm= 0.001 cm) which is usually called the least count of Micrometer.

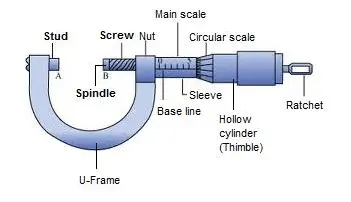

Parts of screw gauge

It consists of a U-shaped metal frame F with a fixed stud A.

- The right moveable and R (called Ratchet) is a cylinder type whose other end is called the spindle.

- A static linear scale or the main scale (usually in mm) is marked on a cylinder.

- The second scale (moveable) is called a circular scale or a cap scale (with 50 or 100 divisions) which is drawn on a cap called thimble ‘T’ fitted over a cylinder.

- The circular scale is designed in such a way that one complete rotation of the cap moves it horizontally by 1 mm on the main scale if circular scale cap moves it horizontally by 1 mm on the main scale if circular scale division is 100 and 0.5 mm in the main scale if the circular division is 50.

Read more about Vernier caliper

Working steps to use of Screw Gauge

- To Find Pitch of Screw

- To Find the Least Count

- To Find Zero Error

The distance moved by linear scale during one complete rotation is called the pitch of the screw. For a screw gauge of 100 circular division, the pitch is 1 mm.

Least count of screw gauge

A screw gauge of 100 divisions will move the cap scale along the main scale by 1/100 of mm-0.01 mm. This is the minimum value up to which a screw gauge can measure and is known as its least count. Or it is defined as the ratio between the pitch of the screw and the number of divisions on the circular scale.

Micrometer least count formula

Micrometer least count in mm

Least count=

L.C= L.C= =0.01 mm

Errors of micrometer

When both ends (stud and spindle) of the screw gauge each other in such a way the zeros of both circular scale and main scale exactly overlap each other, then there is no error. Otherwise, the instruments have an error called zero error. Zero error can be negative or positive.

Negative Zero Error of screw gauge

if the zero of the circular scale above the index line (reference) line, the error is negative. So zero correction will be positive.

Positive Zero Error of screw gauge

If the zero of the circular scale is below the reference line or index line then zero error will be positive. So zero correction will be positive.

Learn about: Types of errors in physics measurement

How to use screw gauge?

Let us find the diameter of the Wire:

- (i) Fix the given wire between the stud and spindle by turning the ratchet in the clockwise direction.

- (ii) Note the main scale reading (M.S.R) (up to complete division visible on the horizontal line just beyond the circular scale.

- (iii) Note the circular scale division says ‘n’ which is exactly in front of the index line or reference line.

- (iv) Multiply ‘n’ with the least count (L.C) to get a fraction of the circular scale reading (C.S.R) to be added into the main scale reading (M.S.R).

- (v) The diameter of the wire will be the diameter of wire= (MSR+ C.S.R) + zero correction.

- (vi) Repeat the experiment at least three times by gipping the wire at different places to obtain its average diameter.

Screw Gauage (video): Visual Explanation

Related posts:

Related Topics In Physics:

| Physics Related Links | |

| Forces | Motion |

| Laws of Motion | Types of capacitors |

| Total Internal Reflection | Reflection of light |

| Ohm’s law | Uses of Laser |

| Types of Physical Quantities | Branches of Physics |

Related Post

Recent Posts

Is energy quantized in classical physics?

No, according to classical wave theory the emission of electromagnetic radiations from the surface is…

Types of laser

Basically, there are four types of laser which includes: Gas Lasers Solid State lasers Liquid…

Ultrasound frequency range

What is ultrasonics? The study and application of mechanical vibrations with frequencies beyond the limits…

Electromagnetic Energy: What are some examples of it?

Electromagnetic energy definition Electromagnetic energy is the amount of energy stored in a region of…

Fundamental units and Derived Units with Examples

The Main Difference between fundamental Units and Base units is that Units that Express base…

Newton’s First law of Motion Examples in Our Daily Life

Newton's first law of motion states that " A body continues its state of rest…

View Comments

Kindly correct the mistake in very first para which is "it can measure upto (1/10) to (1/100) of mm

micro meter list count= 0.5/50( pitch 0.5mm) Thimble division 50

Home » Mechanics » micrometer screw gauge measurement with least count formula

micrometer screw gauge measurement with least count formula

Posted by: admin in Mechanics September 18, 2017 1 Comment 11,187 Views

Advertisement

What is the micrometer screw gauge?

It is an instrument used to measure diameter of thin wires, thickness of small sheets of glass,plastic etc. It can measure upto 1/10 of mm (or 0.01 mm= 0.001 cm) which is usually called the least count of screw gauge.

Parts of screw gauge

parts of screw gauge

It consists of a U-shaped metal frame F with a fixed stud A.

The right moveable and R (called Ratchet) is a cylinder type whose other end is called spindle.

A static linear scale or a main scale (usually in mm) is marked on a cylinder.

The secound scale (moveable) is called circular scale or a cap scale (with 50 or 100 divisions) which is drawn on a cap called thimble ‘T’ fitted over a cylinder.

The circular scale is designed in such a way that one complete rotation of the cap moves it horizontally by 1 mm on the main scale if circular scale cap moves it horizontally by 1 mm on the main scale if circular scale division is 100 and 0.5 mm in the main scale if circular division are 50.

Working steps to use of Screw Gauge

To Find Pitch of Screw

To Find the Least Count

To Find Zero Error

The distance moved by linear scale during one complete rotation is called pitch of screw. For a screw gauge of 100 circular division, the pitch is 1 mm.

Least count of screw gauge

A screw gauge of 100 divisions will move the cap scale along the main scale by 1/100 of mm-0.01 mm. This is the minimum value up to which a screw gauge can measure and is known as its least count. Or it is defined as the ratio between the pitch of the screw and the number of division on the circular scale.

Micrometer least count formula

micrometer least count formula

Micrometer least count in mm

Least count=

L.C= L.C= =0.01 mm

Errors of micrometer

When both ends (stud and spindle) of the screw gauge each other in such a way the zeros of both circular scale and main scale exactly overlap each other, then there is no error. Otherwise, the instruments has an error called zero error. Zero error can be negative or positive.

Negative Zero Error of screw gauge

negative zero error of screw gauge

if the zero of the circular scale above the index line (reference) line, then error is negative. So zero correction will be positive.

Positive Zero Error of screw gauge

positive zero error of screw gauge

If the zero of circular scale is below the reference line or index line then zero error will be positive. So zero correction will be positive.

I think

last sentence "zerocorrection will be positive" is wrong. It is negative.